Enable Automation, Quality Control and Process Optimization in Manufacturing

Transforming Manufacturing with Advanced Computer Vision Technology

Our solution leverages modern computer vision technology to transform manufacturing, significantly enhancing quality control, productivity, efficiency, and safety. By generating synthetic data, it enables defect detection, assembly line inspection, asset tracking, and worker protection, offering a comprehensive solution to meet the complex demands of modern manufacturing.

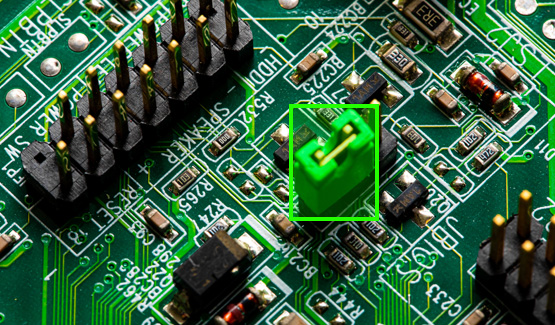

Quality Inspection

Analyse images or video feeds to detect defects, deviations from specifications, and surface imperfections.

Defect Detection

Identify and classify defects in manufactured parts, such as scratches, dents, cracks, or missing components.

Assembly Verification

Detect misplaced or missing parts, misalignments, or assembly errors to help prevent production line downtime and costly rework.

Work Safety

Detect potential safety hazards, such as slips, falls, or collisions, and provide real-time alerts to prevent accidents and injuries.

Inventory Management

Automatically identify and count items, track inventory levels, and facilitate just-in-time inventory replenishment.

Get in touch. Why wait?

Let us help you generate synthetic data on a large scale. Contact us to learn more about our platform and services we can provide!

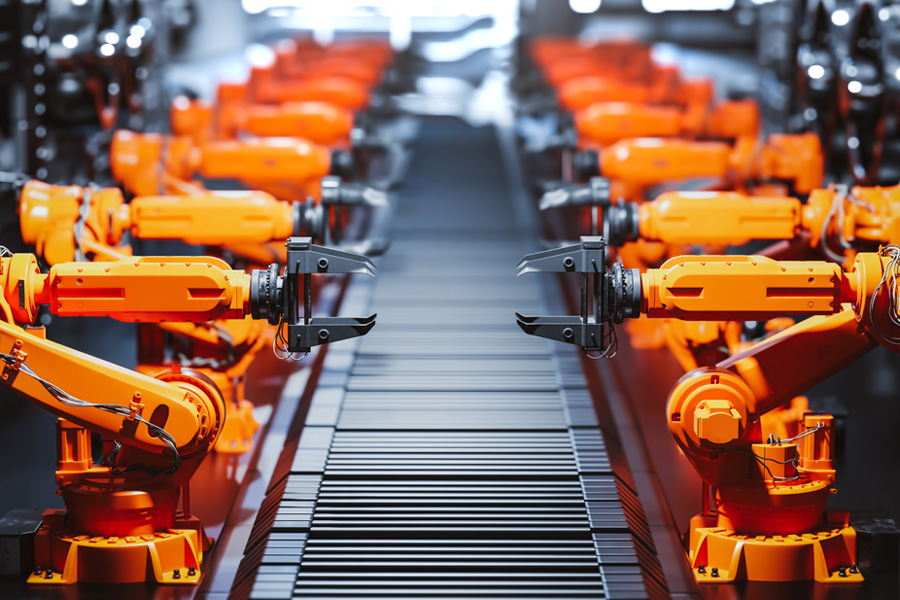

Efficiently Monitoring Product Assembly

Computer vision helps monitor product assembly by analysing images from assembly lines, spotting defects and errors in real-time, and alerting operators for immediate correction. It optimizes processes, improves productivity, and provides insights for continuous improvement. It also ensures product traceability and adapts easily to different assembly sequences or product variations, making it a valuable tool in manufacturing.

The syntheticAIdata Enterprise utilises advanced simulation to generate unlimited datasets, improving model accuracy for monitoring product assembly. By analyzing this data, computer vision systems can detect defects and errors in real-time and prompt operators for immediate action.