- Customer

- Danish Technological Institute

- Industry

- Manufacturing

- Location

- Odense, Denmark

- Platform

- Industrial robots

Customer

The Danish Technological Institute (DTI) is a leading, independent, non-profit research and development organization based in Denmark. It focuses on promoting technological progress and innovation in various industries and sectors. Founded in 1906, DTI provides a wide range of services, including research, testing, certification, and consultancy, to businesses and public organizations.

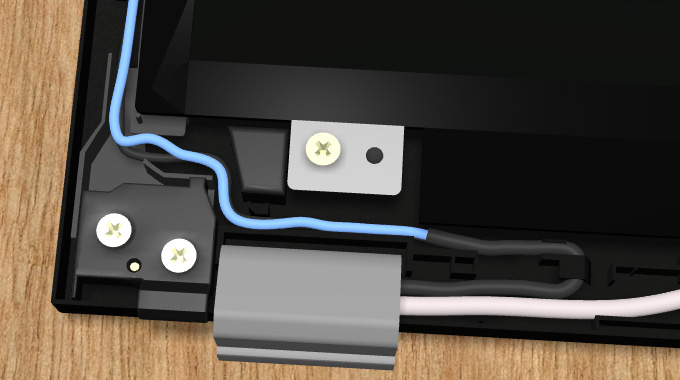

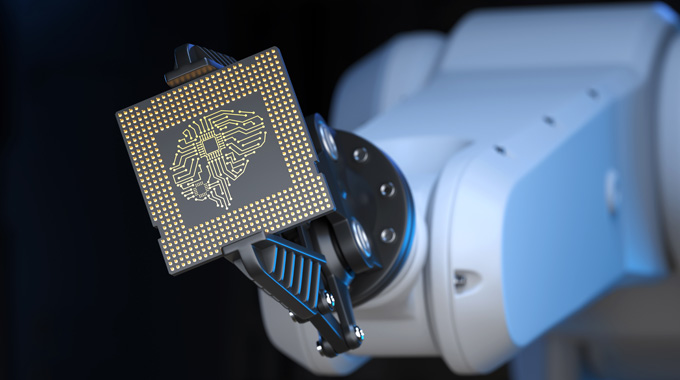

The Danish Technological Institute (DTI), collaborating with other esteemed partners through the RoboSAPIENS (Robotic Safe Adaptation in Unprecedented Situations) project, is transforming remanufacturing with adaptive robotics. These robots tackle complex disassembly tasks, such as unscrewing and destructive processes, by learning from human demonstrations and adapting to uncertain scenarios. A key focus of the project is on refurbishment, with a strong emphasis on renovating products that would otherwise be discarded, aligning with sustainability goals and advancing circular economy practices.

Challenge

Training computer vision models for industrial disassembly robots is difficult because real-world objects, like laptops, are complex and varied. They often have many small, reflective, or hidden parts, which makes them harder for robots to recognize and work with.

Traditional approaches to data collection, which rely on manually labeled images, are time-consuming, costly, and often fail to cover the full range of scenarios the robot might encounter.

Another significant hurdle is training the robots to handle rare or unusual situations, like working with damaged components. These failure cases are crucial for creating a reliable and robust system, yet they are difficult to capture in traditional datasets because such events happen infrequently in real-world settings. Without enough examples of these edge cases, the robot’s performance in critical situations can suffer.

Solution

syntheticAIdata collaborated with DTI to bridge these gaps using synthetic data. By delivering high-quality synthetic images and simulations of laptop disassembly, syntheticAIdata enabled robots to trainon diverse and realistic scenarios, including edge cases. These datasets ensured that the computer vision models were prepared to handle the variability and complexity of real-world disassembly tasks.

This approach accelerated development cycles, reduced costs, and minimized the reliance on manual data collection and annotation, delivering a scalable and efficient solution.

Result

This project established the foundation for industrial-scale disassembly robots, offering innovative solutions for electronic waste recycling. By integrating synthetic datasets, the development process became faster and more cost-effective, significantly enhancing computer vision model performance. This breakthrough prepares robots to manage even rare scenarios with precision, setting a new benchmark for AI-powered, sustainable industrial automation while advancing environmental and industrial efficiency goals.